PROFILE – MATTHEW VINCENT

HOMENEWSPEOPLEPROFILE – MATTHEW VINCENT

Previous

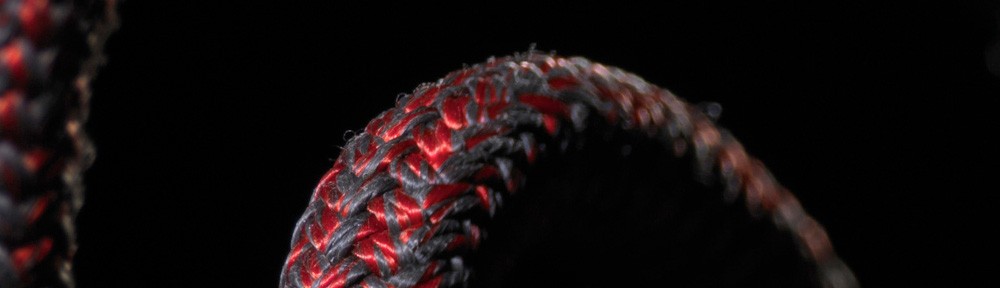

DOLPHIN SAILS HAS MADE SAILS AND COVERS FOR OYSTER YACHTS FOR MORE THAN 30 YEARS

MATTHEW VINCENT IS STILL VERY HANDS ON WITH DOLPHIN SAILS

MATTHEW IN THE 1980S HAND SEWING A CORNER RING IN A SAIL

DOLPHIN SAILS HAS MADE SAILS AND COVERS FOR OYSTER YACHTS FOR MORE THAN 30 YEARS

MATTHEW VINCENT IS STILL VERY HANDS ON WITH DOLPHIN SAILS

Next1

2

3

12 Mar 2020

Email

Share

Facebook

LinkedIn

Twitter

Print

INDUSTRY DATABASE

DOLPHIN SAILS

The descriptor ‘a safe pair of hands’ fits Dolphin Sails MD/chief designer, Matthew Vincent, very well.

In the mid 1960s, when aged ten, he cut Dolphin labels to put on the sails and for every label his father Brian deemed to be ‘good’, he was paid one (old) pence. Some 50 years’ later, Matthew remains ‘hands-on’, running the family sail-making business.

Dolphin Sails was founded in 1964 by boat builders Brian Vincent and Pat Webb. “My father was obsessed with weight saving and together with my stepmother Frances, won the Cherub European Championships in 1970.”

Matthew and younger sister, Toni, grew up some 500m from Dolphin’s HQ in Harwich, and at age six, he joined Harwich Town Sailing Club. His first boat was a Mirror 4808 named ‘slowcoach’. “This was a pretty accurate descriptor as at least three children were faster than me. At around 14, I fortuitously managed to win the Essex schools championship which ignited a passion for sailing and sail-making.”

Olympic trials

Alongside Mirrors, Matthew sailed Cherubs, Condor Cats and Tornados, culminating in Olympic trials where he came fifth. “I then sailed Sonatas, coming second in the nationals, and half tonners, winning our class in Cowes week and the East Anglian offshore.”

After studying physics and astro-physics at the University of London, in 1977 Matthew joined Dolphin, working with his father, stepmother and two machinists, tea-brewing, floor sweeping, making patches and cutting simple sails.

“In the early days of sail design, we rolled out fabric on the floor and shaped the edges with bendy canes; if it was a windy day the sail would have less shape and if there were light winds, it would have more definition which was very bizarre.

“We learned to design in 3D and acquired laser CAD cutting tables to cut sails and covers, ensuring greater accuracy, repeat ability and consistency.”

Additional sites

Dolphin developed a reputation for its dinghy and windsurfing sails, but soon its strong, long-lasting blue water sails came to the fore. “We’ve made sails and covers for Oyster Yachts for over 30 years manufacturing in the UK, exporting a high proportion of our products.”

The business operates from three additional sites – West Mersea, Hamble and Majorca – employing 35 people. “We set up a Majorca loft to support Oyster and the large yacht/super yacht brands and are proud to have supplied the largest yacht in the world.”

As sail designs and fabrics continue to evolve, so too does Dolphin. “Membrane sail development is a focus, and several years ago we invested in ‘form finding’ software which enables cleverly-shaped fabric to enhance the strength and stability of a structure – as was used in the O2 arena.

“We’re writing our own standalone package, which will effectively ‘shrink wrap’ a boat. It will find the contact points, automatically produce shaped-patterns for those areas and ‘form find’ the ‘free’ surfaces, producing unrivalled stability for covers/awnings. It’s a real game-changer for cover and awning design.”

Great thrill

Dolphin’s tensile awnings attract attention from yacht builders and owners, private residences, restaurants and ships.

“Many years ago, we produced a cover for the Planetarium at Madame Tussaud’s for Red Nose day; my daughter Katie contributed to the project and was interviewed by Blue Peter which was a great thrill.”

Matthew singles his father out as his most important mentor and cites career highs as; making his first sail, winning races personally and seeing his sails win races, including the Round Britain and Transat Jacques Vabre. If there was an industry low, Matthew says it ‘must be getting into the windsurf sail market too late and leaving too soon’.

When assessing his industry, Matthew believes offshore manufacturing has driven down costs, resulting in less sail makers employing people with specialist skills. “Fewer young people are working in this sector which is very sad.” And while keen to preserve traditional skills, Matthew describes himself as a ‘disruptor’.

“It’s good to question methodology, keep learning and be innovative. I love to develop new things and look at new ways of working – if you’re passionate about what you do, you can help the market evolve.”

Matthew lives in Essex with wife Kate and their six-year-old daughter. Older daughter Katie lives in Auckland, New Zealand (the land of sails). He plays golf, has a private pilot’s license and is a trustee of his village event ‘Wrabfest’ – a ‘normal fete mixed with a rock festival’.

via Boating Business | Profile – Matthew Vincent.