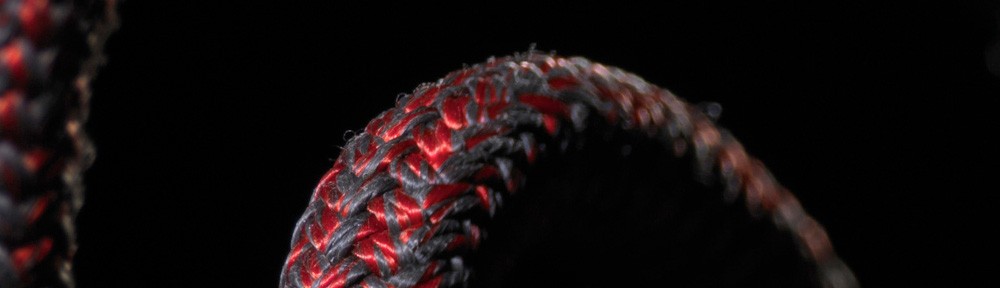

Flax-based biocomposite prototypesBy Rebecca Strong27/07/2022Save articleThe SeaBioComp project has developed a number of demonstrator products showcasing flax-based thermoplastic biocomposites to help reduce the dependence on fossil-based materials in the marine sector. Over the past three years, project partners have been working on two different kinds of biocomposites – a self-reinforced PLA-composite which has been made into a variety of non-woven and woven fabrics suitable for use in compression moulding, and a flax reinforced polylactide or acrylic reinforced composite for use via RIFT, compression moulding and additive manufacturing.A range of products have been developed which do not rely on fossil-based materials Photo: SeaBioCompTesting has shown that, in some cases, these materials outperform conventional non-bio composites currently in use today. The new products have been shown to use the same compression moulding conditions as conventional materials and sometimes the process cycle time can be shorter. The products have also been assessed to ensure they are durable enough for the marine environment.Technically complexThe combination of thermoplastic polymers, natural fibres and 3D printing technologies can produce technically complex designs and applications for the marine environment, say the researchers.A number of prototypes, including a fender and other port structures, have been successfully created using 3D printing as well as scale model offshore wind turbine blades manufactured via monomer infusion under flexible tooling and complex curved structures using compression moulding techniques.The project has produced a series of technical leaflets detailing the various production methods.TopicsBoatbuilding

Source: Flax-based biocomposite prototypes | News | Boating Business