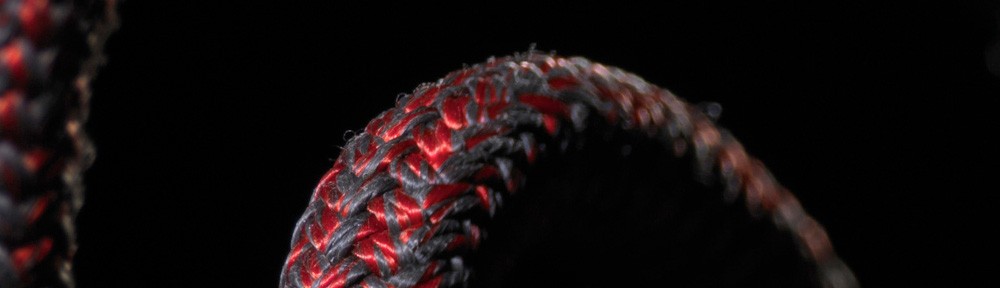

DEEPWATER MOORINGS – LANKHORST FIRST 25 YEARS – THE DRIVE FOR INNOVATION30-04-2024It’s more than 25 years since the first deepwater moorings were successfully installed offshore Brazil – the mooring equivalent of putting a Man on the Moon. Today, the same spirit of innovation is driving the development of a new generation of offshore moorings for the full range of offshore energy platforms, wind turbines, wave devices and solar platforms.In 1998, Portuguese rope maker Quintas & Quintas (now Lankhorst Offshore) had made the decision to diversify their fishing and maritime business units into the offshore market. It was a timely move. There was growing interest in the development of offshore oil and gas fields in ever deeper waters. Traditional methods of mooring: steel wire and chain, the default offshore moorings of the period, were just too heavy for water depths beyond 800m. The self-weight of the mooring line would have required a significantly larger platform than necessary to compensate.Petrobras set the challenge with the requirement for a polyester fiber rope mooring system for PETROBRAS P-36 – the world’s biggest semi-submersible at the time – in the Roncador Field at a water depth of 1360m. The mooring system consisted of 16 legs in a taut leg configuration, each 1800m leg with a minimum break load of 1000 tons. The 1800m polyester legs were divided into three segments for easier handling by anchor handling vessels. The contract for the mooring lines was split among four suppliers including Quintas & Quintas.“ We learned a lot from the first deepwater mooring lines ,” said Sergio Leite, sales director, Lankhorst Offshore. “ We developed the Gama98® (in honor of the Portuguese famous sailor Vasco da Gama) polyester rope construction which involved splicing 12 sub-ropes to produce a 100% torque free rope – something we’d never done before. In 6 months, we had designed a 1000 T break strength mooring rope, double the breaking strength of existing fiber ropes. With every break strength test we learn something new. On the first Break Strength test we were 20% below, on the 2nd test 5% below and on the 3rd test we achieved 1000 T. ”For subsequent deepwater projects, the technical focus shifted to rope manufacturing tolerances. Initially rope length tolerances of +/- 2% for deepwater mooring lines were not uncommon. However, for the Tahiti Spar in the GoM stricter tolerances were required. The spar had 12, 254mm diameter mooring lines, each segment measuring approx. 900m in length and with a MBL of 1907 ton. The mooring lines had to be within +/- 0.5% of the required length after post- installation tensioning. Reducing the rope length tolerance had several practical and financial benefits. Overall mooring line length accuracy is important so that the top chain length can be minimised. A 0.5% line length “safety margin” in the top chain could be worth several millions of dollars on savings to the project.Sergio Leite, again. “For the Tahiti project we developed the industry’s first rope Length Measurement System (LMS) for accurate length measurement under a controlled tension. The rope was pre-tensioned to 1% MBL for a certain length measurement increment. For Tahiti, we produced tether lengths consistently within 1m of the nominal length – an amazing achievement and a first for the deepwater mooring industry.”Committed to optimising deepwater mooring line production for future projects, Lankhorst invested in a new test machine dedicated to testing deepwater tethers. Capable of break testing ropes up to 1200 tonnes MBL, the test facility was the first in fibre rope industry capable of handling test samples up to 20m.Succeeding landmark projects have included Lankhorst Offshore completing the design and manufacture of polyester rope tethers for major projects such as the Thunderhawk semi-submersible, Cascade & Chinook FPSO, Lucius Spar, Goliat FPSO and Aasta Hansteen Spar platform – in 2014, this was the largest single order for deepwater mooring ropes, and believed to be the largest ever order in the global synthetic fibre rope industry. The Goliat FPSO set a world record for the highest Minimum Breaking Load (MBL) ropes ever produced at 2579T, with a diameter of 299mm.Today, the GAMA98® rope construction for deepwater mooring has been replaced by Cabral 512® which uses less twist, with a slight increase in breaking strength and stiffness; overall a rope better suited to deepwater mooring. Cabral 512® rope construction was a development from Lankhorst Euronete Brasil. Meanwhile, GAMA98® rope construction has found new application in floating offshore wind turbines and wave energy devices.Rui Faria, managing director, Lankhorst Offshore is confident of Lankhorst Offshore’s ability to meet the offshore mooring challenges for future offshore energy projects. “ In 2024, we’re able to draw on two World Class production facilities in Portugal and Brazil to meet the growing demand for offshore mooring lines. More

FULLY CERTIFIED CBOS SHEAVE RESISTANT SPLICE FOR DEEPWATER DEPLOYMENT AND RECOVERY30-04-2024The first, fully certified, fibre rope splice for CBOS (Cyclic Bend Over Sheave) use in deepwater deployment and recovery systems has been developed by Lankhorst Offshore. The sheave resistant splice will allow ropes to be lengthened or shortened as needed whilst still retaining the full lifting capacity across the complete rope length. The patented splice development eliminates a weakness that has until now limited the application of spliced fibre ropes in CBOS crane deepwater deployment and recovery systems.End-to-End Rope Splice – Qualification CompleteIn 2023, Lankhorst Offshore reported DNV Endorsement of Qualification Plan End-to-End rope splice for the LANKO®DEEP rope, the company has now completed certification under DNV Technology qualification management and verification DNV-SE-0160. Thereby demonstrating the viability of fibre rope-based, deepwater deployment and recovery projects using smaller vessel sizes when compared with larger vessels needed for steel wire rope.LANKO®DEEP TR is the first crane rope that can be spliced while still retaining the holding capacity in use which is the same as for the unspliced and equally used rope. The technology qualification further extends the utility of LANKO®DEEP by allowing the- joining together of a socket-and-tail termination and a long length of LANKO®DEEP TR crane rope, with a permissible nominal rope diameter difference between the joined ends for socket-and-tail terminations of up to 30%. Attaching a larger diameter tail end, the part expected to wear out the first, creates extra capacity at this part thus increasing the service life and reliability of the overall rope length.- joining together of long lengths of LANKO®DEEP TR rope which includes the cutting of a used rope and splicing-in a length of new or used rope or extending the length of a new or used rope with another length of new or used rope. This allows the reach of the DRS system to be easily modified between projects, or re-spliced in the event of damage to the rope, a significant advantage over steel wire rope.“With the Technology Qualification of LANKO®DEEP TR, Lankhorst has set the standard for the operation of deepwater deployment and recovery systems,” says Sergio Leite, sales director, Lankhorst Offshore. “Designed to maximise deepwater crane performance while increasing uptime availability of the DRS, LANKO®DEEP TR allows rope length to be increased to reach the deepest waters in the world.”For more information on LANKO®DEEP TR and Deepwater Deployment, visit www.lankhorstoffshore.com.

RENEWED ENERGY – NEW OFFSHORE RENEWABLE ENERGY LEAD30-04-2024As Lankhorst Offshore gears up for the next phase in renewable offshore energy, it has appointed Neil Schulz as Global Sales Director for Renewable Energy. Mooring rope construction, end terminations and production optimization are just some areas in the spotlight.Floating offshore wind mooring turbines are the future of renewable wind energy. Bigger and further offshore to maximise their efficiency, however, they face significant mooring challenges. Prior to joining Lankhorst Offshore, Neil Schulz had spent the last three years improving his knowledge of anchors and tensioning equipment for mooring systems at a leading international supplier of subsea anchor systems. It has given him a valuable insight into the dynamics of mooring, developing further his extensive knowledge of fibre rope mooring and deployment.The Offshore renewables energy market brings many new challenges for mooring systems in shallow waters. Depending on the type of the floater concept used, the mooring system may require ropes that are moderately stiff, or very stiff and in some other cases they may require ropes with high elongation to reduce peak loads. Meeting these demands is where Lankhorst Offshore excels and can offer a range of rope products to suit the project requirements for floating offshore wind. Over the past 6 years, Lankhorst Offshore has supplied Gama98® Dyneema® DM20 mooring lines for many floating energy offshore trials. These include WindFloat Atlantic located offshore Viana, Portugal, Kincardine Floating Wind farm, offshore Aberdeen, Scotland, TetraSpar® Demo, offshore Stavanger, Norway and EFGL in the Mediterranean, France.“Because of these projects, we have unique experience of the challenges involved in mooring floating wind turbines,” notes Schulz. “We know what works and what doesn’t work which allows us to direct our research and product development efforts more efficiently. So that when we advise on the best mooring solution for a particular floater, we’re able to back it up with solid engineering know-how.”For more information on Lankhorst Offshore and Renewable Energy contact Neil Schulz, email: [email protected]

Tokyo medallists smash world record for fastest Irish Sea crossingJohn Gimson and Anna Burnet take on challenge to raise awareness of marine pollution27 Sep 23 British Sailing Team athlete John Gimson believes the maritime industry is destined to decarbonise after he and partner Anna Burnet championed sustainable travel while breaking the record for the fastest crossing of the Irish Sea by a sailing craft.Gimson and Burnet took to the Irish Sea on their Nacra 17 on Tuesday (26 September) with the aim of raising awareness of the climate crisis and the problems of environmental degradation in maritime travel, hoping to issue a wake-up call to the industry.They set themselves the challenge of breaking the world record for sailing from Belfast Ballyholme to Port Patrick and back – accompanied by the Artemis eFoiler, a state-of-the-art transport vessel that foils and is electric.Overcoming difficult conditions, the pair managed to comfortably beat the record by seven minutes, returning to Belfast Stranraer just over 90 minutes after their departure. The Team GB sailors, who took home silver from Tokyo 2020, have earned their fair share of plaudits for the feat but this was much more than a record-breaking exercise.The pair, who are partners on and off the water, are striving to bring about change in the maritime industry, hoping to decarbonise a sector that currently accounts for about 2.8% of global greenhouse gas emissions.“There’s obviously the carbon issue,” Gimson said. “I think for people who live in those areas, particularly, I’m sure there’s a lot of health issues within the populations from the fumes of ferries and boats, particularly when the winds blowing into the harbour. Any impact we can make on that will be great.”“We were absolutely shattered when we finished it [the challenge], but very relieved.”The need to go greenWhile recognising the need to push their limits so to truly garner attention and raise awareness for their cause, Burnet admitted to a similar feeling of relief after a physically taxing voyage.Burnet said: “The main reason for us was really to raise awareness of the need to make the marine industry a greener place.“In order to raise awareness, we wanted to do something that was going to be a challenge and that would garner some attention. We’re pretty relieved. It was challenging with the conditions, at times a little scary.”Artemis, headed by two-time Olympic champion Iain Percy, have been supporting their campaign, providing the innovative electric vessel used for the voyage.Aided by the fact Percy is also Gimson and Burnet’s coach, Burnet hailed the relationship built between the pair and the company.She added: “We’ve got great relationships with them, they’re helping us a lot. And they’re all really good people.“Their company is really growing so fast. What they’re on to with this technology is going to be huge. Foiling technology is the future of maritime travel.“It was pretty special for us to come here, to do the challenge with them, and also just see what they’ve got here.”

Ladi Ajayi: growing up with sailing

Ladi Ajayi: growing up with sailing We met Race Across the World’s Ladi Ajayi at West Reservoir Centre to find out more about what first inspired him to sail If you watched the latest series of the BBC’s Race Across the World, you’ll recognise Ladi who took on the challenge alongside his 25-year-old daughter Monique. When he’s not competing on national television, Ladi works as a sport consultant. We caught up with him to find out more about how he discovered sailing aged 13 and what he’d like to see change in the sport for future generations. Growing up and PE lessons Ladi spent his childhood in Hackney, London, growing up in a family of four – although he tells us his extended family is much bigger. “There was always something to do, 24 hours a day. Even as a kid I had a wide circle of friends. It was a brilliant childhood in the sense that there was more freedom to get out and about. Without the electronics, you were physically active all the time and made your own entertainment. “I had friends that were skateboarders, BMX riders, footballers, street hockey players and rugby players. These activities shape the people you become and it’s important to remember that not everyone who comes from deprived areas or inner city are labelled as troublesome. Out of those different places, greatness has come.” Ladi was offered a fantastic range of activities through his local primary and comprehensive school, and it was here that he first discovered his love for sailing. “The education authority at the time was for the whole of London and was very forward thinking so we were able to do things such as ice-skating, badminton and squash as well as the obligatory cross country around the field. It was brilliant in terms of opportunities to taste and try different things.” “Sailing was my thing” “I must have been about 13 when an English teacher decided that this group of particularly boisterous boys might benefit from some kind of adventurous activity, so we were taken in a PE lesson to the North London Banbury Reservoir. “I got in a Wayfarer for the first time, and it was just…wow. That feeling of being in control of something and the freedom- that same evening I got home from school and said, ‘I’m going sailing’.” That evening it took Ladi three buses to get from Hackney to Banbury in North London. “I think the sailing instructors were a bit shocked, they had told me to come back when I was ready but there I was. From then on, I went sailing every day and all weekends too. That was me done.” As well as the sailing, the youth leaders and the instructors at the centre left a lasting impression, teaching life skills that went way beyond what he learnt on the water. “They gave me guidance, taught me how to conduct myself, how to negotiate and meet with people.” He explains. “And those things have stuck with me for life. I then went on to meet all kinds of people through racing and being part of the NSSA (National School Sailing Association). Some of the people I met at these regattas had never seen a black person in their life.” After finishing school, Ladi went to university to study fashion but quickly discovered his career and his heart sat firmly with sport. He returned to college to study recreation and leisure management and today works as Head of Sports at AKD Solutions. “Everybody should feel like they belong” Image courtesy of the BBC “I do think the sport has changed since I was at school in terms of resources available and how you access it. The expense of sport in general has grown so activities that require equipment are prohibited for many families. “Everybody should know their local watersport centre exists and feel like they belong. I know that within the borough of Hackey somewhere there’s a world champion, an Olympian, someone who could be doing the Fastnet, The Ocean Race or SailGP. It’s just we’ve not been able to expose them to the opportunities and wonder of the sport.” Race Across the World Image courtesy of the BBC Did Ladi and Monique have a strategy when they applied for Race Across the World? “No, we didn’t. We pretty much decided to see what happens and just go with it. Monique’s overall strategy was budget which she did really well with – I was denied oranges for the whole journey! “It was actually Monique who wanted to apply for the show and the experience we had was so special. Having that intense long period of time with my daughter was of the main reasons I agreed to do it. It was one of those moments where I’m never going to have the opportunity again.” Don’t miss the full interview with Ladi in the next edition of the RYA Magazine. Read more about our Together on Water strategy.

Five-medal haul for British Sailing TeamOne year out from Paris 2024, Britain’s elite sailors took on the world’s best in Marseille19 Jul 23 Britain’s elite sailors brought home five medals from the Paris 2024 test event – a promising sign just one year out from next summer’s Games.Four silver medals and one bronze were won as fourteen of the country’s best dinghy, windsurf and kite racers took on the world’s best in Marseille, the host city for the Paris 2024 sailing competition.Among those picking up silverware were Tokyo 2020 medallists Emma Wilson, John Gimson and Anna Burnet. Wilson scooped silver in the foiling iQFOiL class, due to make its Olympic debut next summer, while Gimson and Burnet took bronze in the Nacra 17 multihull class.Michael Beckett continued his run of form in the ILCA 7 dinghy class, formerly known as the Laser, narrowly missing the top spot in a final-race battle with Australian Olympic champion Matt Wearn.Ellie Aldridge and Connor Bainbridge completed the podium line-up with silvers in the Formula Kite class, also new for Paris 2024.The path to ParisThe eight-day regatta was the first of four test events run by Paris 2024 organisers to fine-tune their processes – and for the athletes it was a dress rehearsal for the Games with only one entry per nation in each of the ten classes.It was also a key performance indicator in the run-up to Paris 2024, where Britain will aim to maintain its title as the world’s most successful Olympic sailing nation.Mark Robinson, RYA Performance Director, said: “It’s been a great event here in Marseille with a range of conditions to test all involved. With so many equipment changes and new sailors this cycle it was important for us to equal the 2019 Test Event haul of 5 medals as a platform to springboard from for the games proper next year.”Marseille threw plenty of conditions at the sailors over the week, from light, fickle winds to Provence’s famous mistral breeze.Combined with temperatures of up to 37 degrees Celsius it made for tricky racing conditions but provided a useful insight into what the sailors may face next summer.British sailors finished in the top ten in nine of the classes. See the full results.Team GB selectionSelection for the test event was made by the RYA’s Olympic Selection Committee, and is a key step in the RYA’s ongoing process to nominate athletes to go to Paris 2024 as part of Team GB.It doesn’t guarantee that these athletes will be picked to represent Team GB at Paris 2024.The British Sailing Team will have little time to rest and recuperate before heading to the Sailing World Championships in The Hague, The Netherlands.More than 60 British Sailing Team athletes will be among 1,400 sailors from the across the globe expected to attend.The regatta is a once-a-cycle event where the world championship titles for all ten Olympic classes are up for grabs at the same time.It’s also the first opportunity for nations to qualify for a spot on the start line at the Olympics, doubling the significance of the regatta.Find out more about the British Sailing Team and follow their progress on social media at @britishsailing.Images credit: Sander van der Borch/World Sailing

Show dates back to 1969 | News | Boating Business

INDUSTRY NEWS Show dates back to 1969 24/07/2023 Save article The Southampton International Boat Show was founded by Norman Kemish and Arthur Gale in 1969, with the show running for six days with around 50 exhibitors contained within Mayflower Park. SHOW FULLSCREEN SIBS began as a six-day event and expanded to a ten-day event The show was taken over by the British Marine Industries Federation (BMF) in 1983 with the army, supplying a small pontoon for mooring a handful of boats. The running of the show remained with the original organisers. During the early years of BMF ownership, early hovercrafts, water-bikes and concept hydrofoils were amongst the inventions that were given their first showing at the event. In 1986 Richard Branson displayed his Virgin Atlantic Challenger at the show, fresh from an unsuccessful transatlantic crossing, whilst Virgin Atlantic presented a fashion show in the Virgin Atlantic Hall. Other guest appearances included stars of the popular sailing soap, Howard’s Way. In 1988, Arthur and Norman handed over the reins of running the event to BMIF and the event saw a dramatic expansion on the water with 254 boats afloat. SHOW FULLSCREEN SIBS has seen many boat launches over the decades Over the years, the show expanded to a nine-day event, until 1997 when the event was debated by Parliament which granted permission for an extra nautical day of pleasure and the show was extended to ten days. Key dates in the history of the show include its first celebrity chef, Ross Buden, in 2004. The show has since worked with Anthony Worrall-Thompson, Jean-Christophe Novelli and James Martin and Si King and Dave Myers (a.k.a. The Hairy Bikers). SHOW FULLSCREEN Southampton Boat Show in 1993 In 2005, the event featured a makeshift beach, with tonnes of sand imported. In 2012, the show welcomed the successful sailing Team GB, fresh from the 2012 London Olympics and Paralympics. Visitors to the show also witnessed the Royal Marines attempting a 24-hour underwater 240-mile cycle. The first passenger boat was introduced in 2017 and in 2019, the show broke previous records with 600+ marine brands, 240+ boat and product debuts and 103,000 attendees. The 2020 edition of the show was cancelled due to the ongoing global pandemic COVID-19 but in 2022, the show bounced back with 685 stands and berths covering a 70,000+ sqm footprint. More than 650 craft were on display, with around 300 boats berthed in the marina. Topics Industry News

Peters & May celebrates 50 years in business | News | Boating Business

Peters & May celebrates 50 years in business 19/07/2023 Save article Peters & May began life in 1973 as a small freight forwarding company operating in Reading UK. SHOW FULLSCREEN Peters & May yacht shipping Fast forward 50 years, the company is celebrating its 50th anniversary as a logistic provider operating around the world. The company has its UK HQ in Southampton and also occupies ten global offices, across Europe, Asia and the US, employing more than 100 staff members. It first became a key player in the marine industry during the 1980’s by providing logistics for prestigious events such as the Americas Cup and the Whitbread Round the World Race. From then on, it has expanded continuously, broadening its scope to offer transport and shipping services in areas such as yacht racing, leisure boating, commercial cargo, general freight forwarding, and courier services (CEC). In recent years, the yacht shipping industry has witnessed significant technological advancements in hull designs, revolutionising boat performance and sustainability. SHOW FULLSCREEN Peters & May staff have celebrated 50 years of the company being in business While the standard shipping methods for yachts, such as roll-on/roll-off or lift-on/lift-off have remained unchanged, these innovations have necessitated adaptations to lifting equipment and requirements. From international customs protocols to cradling and deck lashings, Peters & May has improved its craft and built its knowledge base using high-quality equipment to deliver customer-tailored lifts. Despite facing numerous challenges, such as global price rises, port closures, labour and cargo capacity shortages, Peters & May has reported increased shipments across all divisions, making 2022 one of its most successful years to date. Topics Industry News

Source: Peters & May celebrates 50 years in business | News | Boating Business

New rope cutter from Yanmar | News | Boating Business

BOATBUILDING New rope cutter from Yanmar 21/07/2023 Save article Yanmar Marine International (YMI) is introducing its first rope cutter, an easy-to-install safety feature designed solely for sailing yachts equipped with the Yanmar SD60 sail drive and fixed two or three blade propellers. SHOW FULLSCREEN Yanmar Marine International has introduced its first rope cutter The rope cutter is suitable for both mono hulls and catamarans, with the aim of enhancing safety and reducing maintenance costs and downtime. A circular saw blade is mounted directly onto the shaft behind the propeller which turns with the shaft to stop ropes, weeds, plastic and fishing lines from jamming between the cutlass and the propeller. It is available for OEMs or as a spare part. “As the industry’s first rope cutting solution designed exclusively for the SD60, the Yanmar Rope Cutter provides a simple and effective solution, preventing the need for external intervention should the propellor become compromised,” said Justin Hogen, product manager, Yanmar Marine International, said. “The issue of yacht propellers catching rope, nylon fishing lines, nets and other plastic hazards floating in the water is a problem faced by sailors, which can result in significant damage, costly repair bills and frustrating downtime. “When the propeller comes into contact with waste, it can wrap itself around the sail drive/propeller shaft which can prevent the shaft from rotating, and manoeuvring will become impossible.” The SD60 is a Yanmar designed and developed sail drive, available with two bell housing sizes for compatibility with the company’s 3JH5E, 3JH40, 4JH5E, 4JH45, 4JH4-TE, 4JH57, and 4JH80 engines. Topics Engines & Propulsion

Source: New rope cutter from Yanmar | News | Boating Business

Barton brings new life to Tufnol blocks | News | Boating Business

AFTERMARKET Barton brings new life to Tufnol blocks 14/07/2023 Save article Barton Marine has unveiled a number of new products including the resurrection of the Tufnol Tuphblox range. Originally developed following the second world war, these fabric-based laminated plastic blocks fell out of favour in the 1970s when fully plastic blocks became the norm. Source: Barton Marine Barton’s T-Track conversion inserts Now 50 years later, Barton has spotted the need to support heritage vessels worldwide and has relaunched the Tuphblox range. The company has also unveiled its new T-Track conversion insert, the ‘solution to a historical marine industry problem’. “If you go back in history the 32mm T-Track produced around the late 1970s and through the 1980s was 32mm with a 6mm lip,” said the company. “This has now moved to a 5mm lip as an industry standard. As such all the cars have been redesigned around this 5mm standard and the 6mm gap cars are no longer available. Older vessels with this 6mm track are now facing not only the cost of new cars but also replacement track.” To solve this problem, Barton has created inserts which can be fitted to any of the Barton 32mm Genoa cars, converting them from a 5mm to a 6mm track. Finally the company has released a new size 2 double stanchion lead block (N02290 – 2023 model). Mounted on to the stanchion base, the revised block now features a removable clevis pin and ring which allows for continuous furler lines to be easily installed in situ. Available in plain bearing or ball bearing configuration, this block fits 25mm diameter steel tubing and has a safe working load of 370kg. Topics Masts, spars, sails & rigging

Source: Barton brings new life to Tufnol blocks | News | Boating Business