Email Print

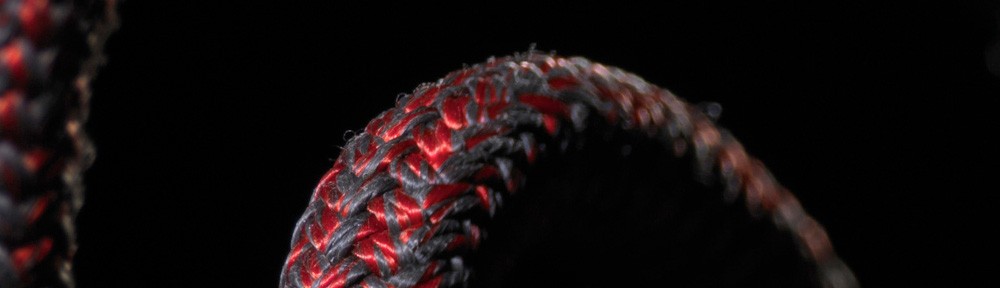

Development in rope coatings sets companies apart

Rope technology has seen significant developments over the past three decades. From revolutionary new fibres of cores and covers that impact on strength to dramatic advances in the levels of rope durability, diameter, stretch and creep.

For Marlow Ropes, much of the current development is on the coatings and techniques after production of the rope to improve its performance, longevity and resistance to fatigue.

“Everyone is using the same materials,” explained Paul Dyer, Marlow’s’ technical manager. “The ability to do something with it, something that stands out, is important. The product hinges on the coatings and what we can add to the cover afterwards.

“Much of our development has gone into coatings, to improve fatigue life, abrasion resistance and coefficient of friction.”

And he explained how some are offered as standard, such as its Armourcoat, that will protect single and double braided fibre ropes, while other are offered as optional extras to gain additional benefits such as reducing the fatigue and extending life.

“It’s a continual balance between costs, performance and ease of use,” he said. “Race boats such as America’s Cup teams will specify almost anything they like.

“What we learn from these users at the cutting edge of the sport often ends up in chandleries as later product developments.

“There is much more development to be done with coatings to get further performance benefits and enhance the material’s properties and so improve the final product.”

via Boating Business | Development in rope coatings sets companies apart.