CONSISTENCY IS ALL IMPORTANT

HOME NEWSAFTERMARKETMASTS, SPARS, SAILS & RIGGING CONSISTENCY IS ALL IMPORTANT

21 Jun 2018

Share

Seldén is about to deliver its 750th J/70 mast, photo credit RYA Paul Wyeth

INDUSTRY DATABASE

SELDEN MASTS LTD

The benefits of a carbon rig – its lighter and stiffer than other metals – and the performance, control and increased comfort when sailing are well recognised. But the key is ensuring consistency, says Seldén.

The company produces more than 400 carbon spars, plus booms, poles and bowsprits for boats ranging from one design to some of the world’s most prestigious cruising yachts.

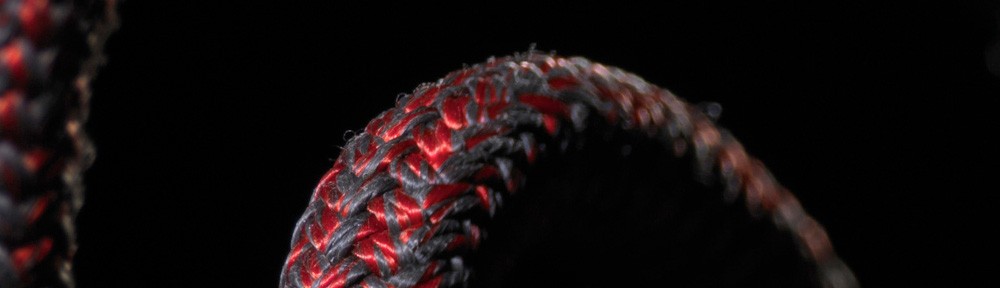

All Seldén spars are made from pre-preg carbon, with the fibre coated in the precise amount of epoxy resin for optimum lamination, ensuring a lighter stronger spar.

Accuracy

Seldén’s automated Mandrel Filament Moulding uses carbon tow, a ribbon of carbon fibres held together by the uncured resin. Computer controlled for accuracy, consistency and repeatability, this ensures every mast meets the exacting requirements of its owner or class.

“In one design consistency is critical. For example, our 750th J/70 mast is about to be delivered and every mast is tested to perform exactly the same,” explained James Harris, head of sales at Seldén.

Composite processes

When Tracey Edwards’ iconic Farr 58, Maiden, sets sail later this year she will have a new Seldén mast.

The original mast was bespoke aluminium, but today the company is using modern composite processes and Seldén’s unique winding technique will be used to produce the necessary laminate and reinforcement specifications.

A key component in producing a string laminate is to use precisely the correct balance of heat and pressure to squeeze and cure the spar.

All Seldén carbon spars are cured in a computer-controlled autoclave pressurised oven to ensure optimum consolidation of the laminate to produce the most consistent product possible.