NEW BLOCKS FROM ALLEN BROS

HOMEXPORT BBMETSTRADENEW BLOCKS FROM ALLEN BROS

Allen Bros blocks are made from recycled plastic

INDUSTRY DATABASE

ALLEN BROTHERS (FITTINGS) LTD

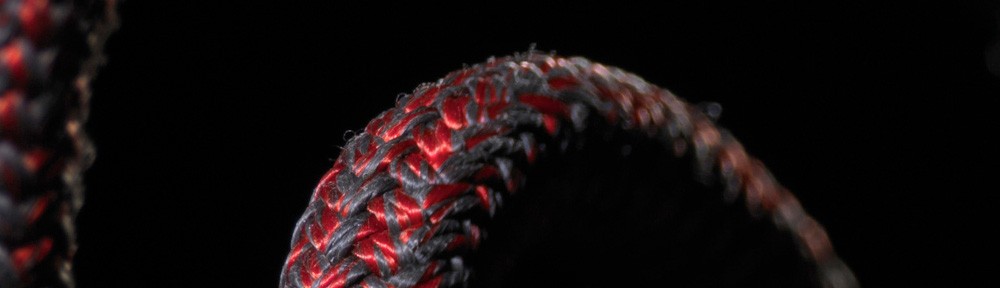

Allen Bros has a new range of plain bearing blocks using 100% recycled plastics and 20% less material than the previous version.

The blocks use the outer cheek and ultra-strap from the 20 and 30mm dynamic range, allowing Allen Bros to manufacture the products more efficiently.

It also helps to reduce the long-term impact of plastics and un-recyclable materials on the environment.

The new range also features a grey sheave to differentiate them from the existing dynamic range, that has black sheaves.

The blocks’ static loading capabilities makes them suitable for take-up systems or applications that don’t require high dynamic performance.

Loading points

In addition, Allen Bros launched a new pivoting mast step earlier in the year, designed for dinghies or small keelboats that have easily adjustable rigging whilst sailing.

The design has been developed to reduce loading points in the deck of the boat when the mast pivots, spreading

the forces more evenly.

Having a pivoting mast step and heel also allows for a consistent mast bend profile resulting in more accurate rig setup.

The mast step is CNC machined from 6082 aluminium and anodised black. The mast heel is made from nylon and currently available in three diameters, 37.5mm, 41mm and 45mm.

Allen Bros will be on stand 03.216 at METSTRADE.