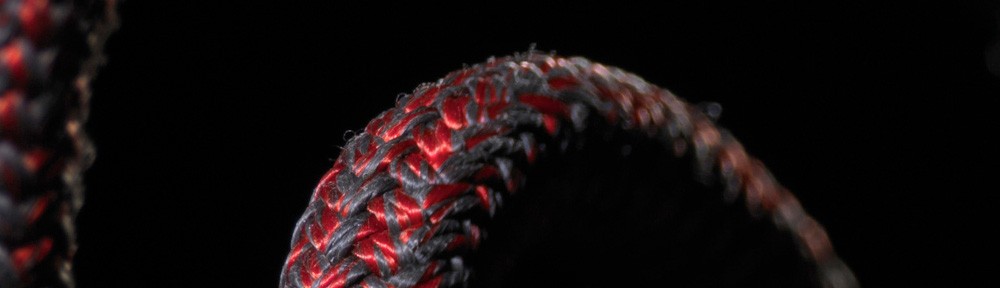

DEEPWATER MOORINGS – LANKHORST FIRST 25 YEARS – THE DRIVE FOR INNOVATION30-04-2024It’s more than 25 years since the first deepwater moorings were successfully installed offshore Brazil – the mooring equivalent of putting a Man on the Moon. Today, the same spirit of innovation is driving the development of a new generation of offshore moorings for the full range of offshore energy platforms, wind turbines, wave devices and solar platforms.In 1998, Portuguese rope maker Quintas & Quintas (now Lankhorst Offshore) had made the decision to diversify their fishing and maritime business units into the offshore market. It was a timely move. There was growing interest in the development of offshore oil and gas fields in ever deeper waters. Traditional methods of mooring: steel wire and chain, the default offshore moorings of the period, were just too heavy for water depths beyond 800m. The self-weight of the mooring line would have required a significantly larger platform than necessary to compensate.Petrobras set the challenge with the requirement for a polyester fiber rope mooring system for PETROBRAS P-36 – the world’s biggest semi-submersible at the time – in the Roncador Field at a water depth of 1360m. The mooring system consisted of 16 legs in a taut leg configuration, each 1800m leg with a minimum break load of 1000 tons. The 1800m polyester legs were divided into three segments for easier handling by anchor handling vessels. The contract for the mooring lines was split among four suppliers including Quintas & Quintas.“ We learned a lot from the first deepwater mooring lines ,” said Sergio Leite, sales director, Lankhorst Offshore. “ We developed the Gama98® (in honor of the Portuguese famous sailor Vasco da Gama) polyester rope construction which involved splicing 12 sub-ropes to produce a 100% torque free rope – something we’d never done before. In 6 months, we had designed a 1000 T break strength mooring rope, double the breaking strength of existing fiber ropes. With every break strength test we learn something new. On the first Break Strength test we were 20% below, on the 2nd test 5% below and on the 3rd test we achieved 1000 T. ”For subsequent deepwater projects, the technical focus shifted to rope manufacturing tolerances. Initially rope length tolerances of +/- 2% for deepwater mooring lines were not uncommon. However, for the Tahiti Spar in the GoM stricter tolerances were required. The spar had 12, 254mm diameter mooring lines, each segment measuring approx. 900m in length and with a MBL of 1907 ton. The mooring lines had to be within +/- 0.5% of the required length after post- installation tensioning. Reducing the rope length tolerance had several practical and financial benefits. Overall mooring line length accuracy is important so that the top chain length can be minimised. A 0.5% line length “safety margin” in the top chain could be worth several millions of dollars on savings to the project.Sergio Leite, again. “For the Tahiti project we developed the industry’s first rope Length Measurement System (LMS) for accurate length measurement under a controlled tension. The rope was pre-tensioned to 1% MBL for a certain length measurement increment. For Tahiti, we produced tether lengths consistently within 1m of the nominal length – an amazing achievement and a first for the deepwater mooring industry.”Committed to optimising deepwater mooring line production for future projects, Lankhorst invested in a new test machine dedicated to testing deepwater tethers. Capable of break testing ropes up to 1200 tonnes MBL, the test facility was the first in fibre rope industry capable of handling test samples up to 20m.Succeeding landmark projects have included Lankhorst Offshore completing the design and manufacture of polyester rope tethers for major projects such as the Thunderhawk semi-submersible, Cascade & Chinook FPSO, Lucius Spar, Goliat FPSO and Aasta Hansteen Spar platform – in 2014, this was the largest single order for deepwater mooring ropes, and believed to be the largest ever order in the global synthetic fibre rope industry. The Goliat FPSO set a world record for the highest Minimum Breaking Load (MBL) ropes ever produced at 2579T, with a diameter of 299mm.Today, the GAMA98® rope construction for deepwater mooring has been replaced by Cabral 512® which uses less twist, with a slight increase in breaking strength and stiffness; overall a rope better suited to deepwater mooring. Cabral 512® rope construction was a development from Lankhorst Euronete Brasil. Meanwhile, GAMA98® rope construction has found new application in floating offshore wind turbines and wave energy devices.Rui Faria, managing director, Lankhorst Offshore is confident of Lankhorst Offshore’s ability to meet the offshore mooring challenges for future offshore energy projects. “ In 2024, we’re able to draw on two World Class production facilities in Portugal and Brazil to meet the growing demand for offshore mooring lines. More

Marlow Rope Sales

The Information Portal of Boatropes.co.uk